Lockout and Tagout should always be used together to maximize safety

- Share

- Issue Time

- Sep 12,2024

Summary

Lockout and Tagout should always be used together to maximize safety

All workers could be exposed to the dangers of hazardous energy. Workers need to be familiar with when lockout/tagout is needed and what to do if they find it in use in the workplace.

Lockout/tagout is a set of procedures that ensures hazardous energy sources are shut off during service and are unable to be reactivated (or turned on) until the work is completed.

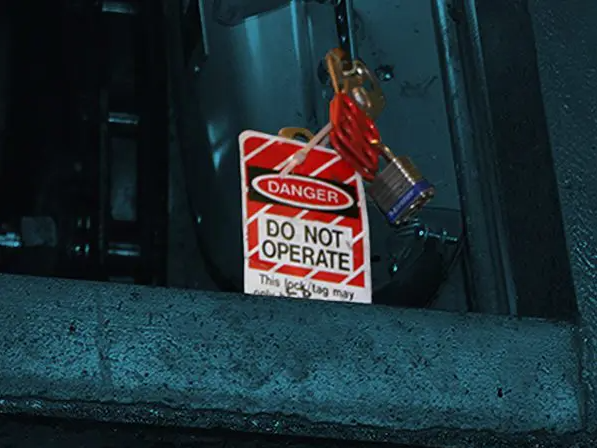

Lockout refers to the act of placing a physical barrier, such as a lock, cover or chain, that prevents a machine or equipment component from being turned on or activated.

Tagout is the application of a label or tag placed near the lockout that alerts others to the lockout status of the equipment.

Lockout and Tagout should always be used together to maximize safety.

There may be several different types of hazardous energy that workers can be exposed to on the job. It is important for all workers to know what hazards could be present in their workplace. Types of hazardous energy include:

Chemical - chemicals that may be stored in pipes, tanks, and/or held under pressure.

Pneumatic - trash compactors, compressors, lifting equipment.

Thermal - extreme heat from heating elements or furnaces or cold energy from refrigeration units or compressed gases.

Electric - electrical equipment which is either wired or operated by cord and plug.

Mechanical - stored energy in rotating or moving parts or conveyor belts.

Other - such as x-ray, radiation, laser, microwave, radio frequency, or others.

Lockout devices are designed to keep the equipment from being turned on or to keep the energy source from being released.

Lita Lock, a China based manufacturer, since 2017, active in manufacturing safety padlocks, electrical lockout, valve lockout, lockout station, tags and other lockout & tagout for global partners.

To help customers compliance with OSHA Standard 29 CFR 1910.147, Lita Lock does not only offer design, production and final assembly, but also a complete lockout & tagout solution for various industries.

Lita Lock pursues the competitiveness on creative, quality control, technology and sustainable development. As the founder of Lita Lock, Iris Chen says: “Many things have changed, but one thing that has not—our original intention to start businesses: keeping workers safe.” Together, we make work environments safer.

Sales Manager: Iris Chen

Email: iris@litalock.com

Whatsapp: + 86 13165872593

Keywords: #lockouttagoutlocks #safetypadlocks #lockouttagout #totallockout #masterlock #bradyloto #loto #elecricallockoutkit #valvelockoutdevices #MCBlockoutkit #cautionsign #securitysign #OSHA #lockouttagoutprocedure #safetytags #lototags #lockoutdevices #lockedout #safetysupply #safetyppe #safetylockouts #ballvalvelockout #cablelocks #valvelocks #lotodevices #litalock #circuitbreakerlockoutdevices #breakerlockouts #circuitbreakerlockout #tblo #lockoutwire #electricallockouttagoutkits