Common Mistakes In Lockouts And Lockout Device Calculator

- Share

- Issue Time

- Aug 16,2024

Summary

Estimate the number of devices needed on a per-facility basis

Lockout device calculator:

Estimate the number of devices needed on a per-facility basis

The total number of lockout devices needed for your lockout tagout system will vary by organization. Here’s one way to determine a good estimate for your organization:

1. Decide how many stations or departments need a lockout device cabinet or board.

2. Discuss with authorized employees where the cabinet or board should be located based on the location of equipment, with high-volume equipment areas being the key factor for lockout tagout station placement.

3. Look at the high-hazard equipment areas (boiler, chiller, generators and facilities equipment rooms) and production departments. Count the total number of devices required for all the written machine-specific procedures in the desired area and order 10% of the total number of devices. If the boiler room has 50 pieces of equipment and 100 ball valve devices, the boiler lockout station should have 10 ball valve devices. The need to lock out all equipment at your facility should never happen, but placing an initial order of 10% will be a good starting point.

4. Monitor lockout station devices with an inventory list to see if more devices need to be ordered after the initial order.

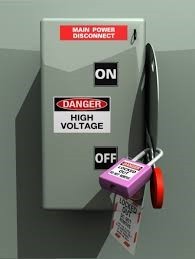

Common mistakes in lockouts:

-Leaving keys in the locks.

-Locking the control circuit and not the main disconnect or switch.

-Not testing the controls to make sure they are definitely inoperative.

Review the Following Points:

*Equipment should be locked out while being repaired.

*Lockout means to place a lock on a device that prevents energy release.

*Tagout means to place a tag on a switch or other shut off device that warns not to start that piece of equipment.

*Make sure to remove keys from the locks.

*Lock the main switch.

*Test the controls to make sure they are definitely inoperative.

*Replace all guards on the machinery after servicing.

Lita Lock, a China based manufacturer, since 2017, active in manufacturing safety padlocks, electrical lockout, valve lockout, lockout station, tags and other lockout & tagout for global partners.

To help customers compliance with OSHA Standard 29 CFR 1910.147, Lita Lock does not only offer design, production and final assembly, but also a complete lockout & tagout solution for various industries.

Lita Lock pursues the competitiveness on creative, quality control, technology and sustainable development. As the founder of Lita Lock, Iris Chen says: “Many things have changed, but one thing that has not—our original intention to start businesses: keeping workers safe.” Together, we make work environments safer.

Sales Manager: Iris Chen

Email: iris@litalock.com

Whatsapp: + 86 13165872593

Keywords: #lockouttagoutlocks #safetypadlocks #lockouttagout #totallockout #masterlock #bradyloto #loto #elecricallockoutkit #valvelockoutdevices #MCBlockoutkit #cautionsign #securitysign #OSHA #lockouttagoutprocedure #safetytags #lototags #lockoutdevices #lockedout #safetysupply #safetyppe #safetylockouts #ballvalvelockout #cablelocks #valvelocks #lotodevices #litalock #circuitbreakerlockoutdevices #breakerlockouts #circuitbreakerlockout #tblo #lockoutwire #electricallockouttagoutkits