Unlocking the Potential of Valve Lockouts: Critical Applications Across Industries

- Share

- Issue Time

- Nov 1,2024

Summary

Today, let's explore the versatile applications of valve lockouts and understand why they are a cornerstone of industrial safety and efficiency.

In the intricate tapestry of industrial operations, where the symphony of machinery and processes must operate in harmony, the humble valve lockout stands as a guardian of safety and reliability. Often overlooked but critically important, valve lockouts serve as an indispensable tool in a wide array of industries, ensuring that valves remain securely positioned, preventing unauthorized access, and mitigating the risk of accidents. Today, let's explore the versatile applications of valve lockouts and understand why they are a cornerstone of industrial safety and efficiency.

1. Ensuring Maintenance Safety

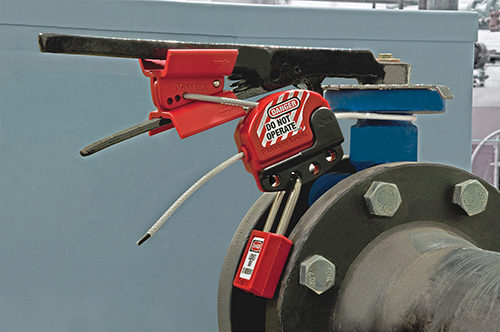

In the hustle and bustle of daily operations, the need for routine maintenance cannot be overstated. Valves, as essential components in fluid systems, require periodic inspections and repairs. Valve lockouts come into play here by securing valves in a specificposition – fully open, fully closed, or partially open – during maintenance procedures. This prevents unintended valve movement, thereby safeguarding workers from potential hazards such as unexpected fluid release or pressure changes.

By utilizing valve lockouts, businesses can comply with industry safety standards and practices, such as lockout/tagout (LOTO) procedures, which aim to prevent equipment from being accidentally energized or operated during maintenance. A clearly labeled lockout not only physically restricts access but also serves as a visual reminder of the ongoing maintenance activity.

2. Preventing Misoperations and Accidents

In complex industrial environments, misoperations can lead to severe consequences, including spills, leaks, equipment damage, and even personal injuries. Valve lockouts mitigate these risks by preventing unauthorized access to critical valves. Whether it's due to human error, mischievous tampering, or miscommunication, a securely locked valve stands as a steadfast barrier against potential mishaps.

For instance, in chemical plants where handling hazardous materials is the norm, ensuring that valves controlling these substances remain in their designated states is paramount. Valve lockouts offer a robust solution, preventing any unintended valve manipulation that could lead to dangerous spills or reactions.

3. Facilitating Process Control and Efficiency

Beyond safety, valve lockouts also play a pivotal role in maintaining process control and enhancing operational efficiency. By securely locking valves in place during specific processes, companies can ensure that systems operate as intended, without unplanned disruptions. This consistency is critical in continuous production environments, where downtime can significantly impact productivity and profitability.

Moreover, the advent of smart valve lockouts, equipped with sensors and digital connectivity, allows for real-time monitoring and tracking of valve status. This technological advancement not only enhances safety but also facilitates predictive maintenance, enabling businesses to preemptively address potential issues before they escalate into larger problems.

4. Compliance and Documentation

Valve lockouts also support compliance with regulatory requirements and internal safety policies. By integrating lockout/tagout practices with valve lockouts, businesses can maintain comprehensive documentation of valve status, maintenance activities, and associated personnel. This information is invaluable in the event of audits, incident investigations, or performance reviews.

Conclusion

Valve lockouts are more than just hardware devices; they are an integral part of a robust industrial safety framework. Their versatile applications across industries underscore their importance in ensuring safety, preventing accidents, maintaining process control, and enhancing operational efficiency.

As industries continue to evolve, so too must our approach to safety. By embracing advanced valve lockout technologies and maintaining vigilant adherence to safety protocols, we can build a safer, more reliable industrial landscape. Let's commit to integrating valve lockouts into our operations, ensuring that they remain a silent yet powerful sentinel of industrial safety and efficiency.

Lita Lock, a China based manufacturer, since 2017, active in manufacturing safety padlocks, electrical lockout, valve lockout, lockout station, tags and other lockout & tagout for global partners.

To help customers compliance with OSHA Standard 29 CFR 1910.147, Lita Lock does not only offer design, production and final assembly, but also a complete lockout & tagout solution for various industries.

Lita Lock pursues the competitiveness on creative, quality control, technology and sustainable development. As the founder of Lita Lock, Iris Chen says: “Many things have changed, but one thing that has not—our original intention to start businesses: keeping workers safe.” Together, we make work environments safer.

Sales Manager: Iris Chen

Email: iris@litalock.com

Whatsapp: + 86 13165872593

Keywords: #lockouttagoutlocks #safetypadlocks #lockouttagout #totallockout #masterlock #bradyloto #loto #elecricallockoutkit #valvelockoutdevices #MCBlockoutkit #cautionsign #securitysign #OSHA #lockouttagoutprocedure #safetytags #lototags #lockoutdevices #lockedout #safetysupply #safetyppe #safetylockouts #ballvalvelockout #cablelocks #valvelocks #lotodevices #litalock #circuitbreakerlockoutdevices #breakerlockouts #circuitbreakerlockout #tblo #lockoutwire #electricallockouttagoutkits